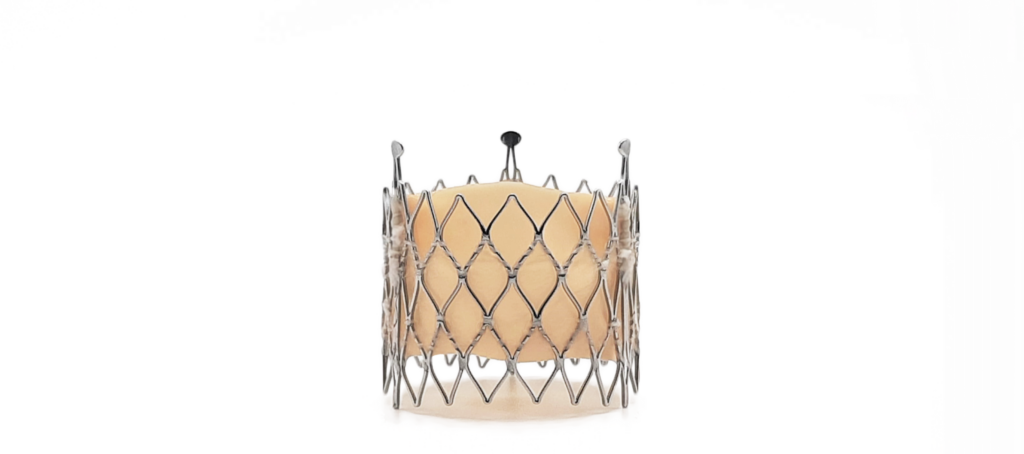

Optimum TAVI System

Optimum TAV TM

Designed for durability

Unique natural valve geometry

Optimized geometry and leaflet dynamics mimic the natural valve and maximize hemodynamic performance.

NO suture holes in flexion zone

Having no suture holes in any moving part of the valve is essential for maximum durability. This includes the flexion zone, where disease begins.

Self-expanding frame

Avoids balloon-expansion and the associated high pressure that may damage valve tissue. Strong enough to treat bicuspid patients.

LOWEST valve height

Lowest self-expanding valve height. Allows full access to coronary arteries. Reduces risk of conduction disturbances. Intra-annular leaflets. Designed for valve-in-valve implantation.

Innovative leaflet design

3 leaflets constructed from only ONE piece of tissue, for less sutures and increased durability. NO preformed (3D) leaflets for more natural motion.

Tall tissue skirt

Pliable porcine pericardial tissue skirt with greater sealing surface located directly behind leaflets, not below them, to better prevent paravalvular leak.

Trusted materials

Bovine pericardial tissue leaflets and nitinol frame offer materials with established durability.

Advanced tissue treatments

Features tissue treatments for flexion and anti-calcification, for less valve stress and more durability.

Precision 2 TM Catheter

18F Transfemoral system offering simplified, accurate positioning

Automatic axial alignment

The Optimum TAV reorients as it is deployed, resulting in complete axial alignment with the native valve.

Repositionable

The Optimum TAV is fully repositionable after partial deployment for precise placement.

Retrievable

The Optimum TAV may be fully recaptured and retrieved from patient.

Short capsule

Easier to maneuver challenging anatomy.